- : KAIZHENG

- : CHINA

- : To be confirmed

- : Sufficient

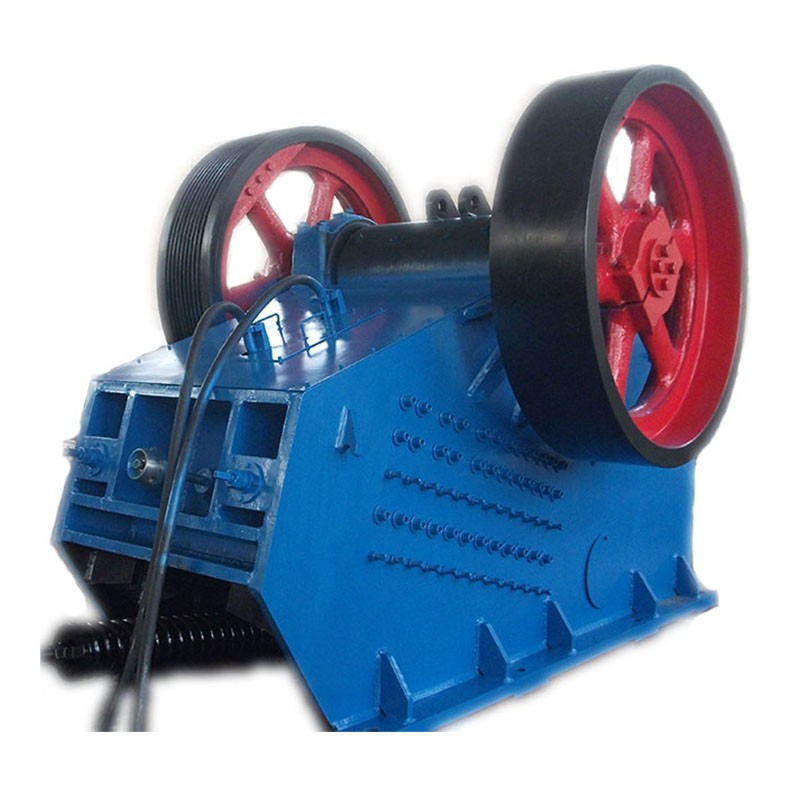

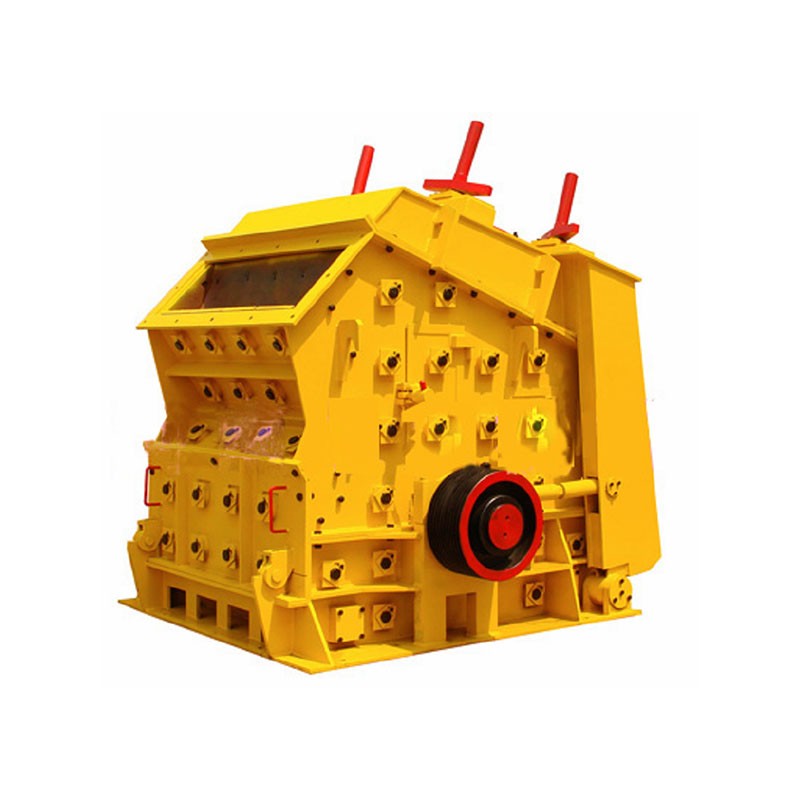

PE, PEX, PE(X)Y (hydraulic) are new jaw crushers designed by our company, based on the research of other country's jaw crusher technology. It is an optimized equipment for crushing different kinds of rough rocks. The PE(X)Y series is a hydraulic protective jaw crusher, which is mainly used for coarse crushing of steel slag and ferroalloy.

Applicable industries: Widely used in metallurgy, mining, chemical, cement, construction, refractory materials and ceramics industries.

Applied materials: Jaw crusher is suitable for crushing ore, rock, slag and other materials whose compressive strength is not higher than 320Mpa.

Features:

According to different materials, the jaw plates are varies with different tooth types and thickness of high manganese steel alloy jaw plate.There are manganese steel, modified manganese steel and super high manganese steel materials for choice, and among them, the life time of super high manganese steel is 2.6 times longer than ordinary manganese steel.

It adopts simple, safe and convenient adjustment system of double wedge ore discharge.

The jaw breaker can be installed in an integrated way of motor base and crusher frame, which can reduce the space of crusher installation and save the cost of basic construction. For larger machines, the method is to install motor and crusher seperately.

Advantages:

It can set the rated load of the machine, and can be used for selective crushing for materials with different compressive strength.

Its reliable protection system and the automatic elimination of non-breakable material can effectively solve the problem of "stuck steel" in the crushing of steel slag, to achieve uninterrupted production.

Referring to client's needs, it is optional for:

Automatic grease lubrication system.

Hydraulic adjustment system for discharge.

Temperature and rotating speed sensor and material level detection device of crushing chamber.

Rubber damping device, which can effectively reduce the impact force to the foundation.

Technical parameters:

PE/PEX Series:

| Model | Maximum material granularity(mm) | Discharge port size(mm) | Capacity(m3/h) | Speed of main shaft (r/min) | Power (kw) | Weight(t) |

| PE250×400 | 210 | 20-80 | 45030 | 280 | 15 | 2.2 |

| PE400×600 | 320 | 40-100 | 16-40 | 300 | 30 | 6.5 |

| PE350×1000 | 280 | 70-120 | 40-85 | 300 | 55 | 10.6 |

| PE500×750 | 425 | 50-100 | 20-43 | 275 | 55 | 9.5 |

| PE600×900 | 480 | 75-200 | 35-120 | 255 | 75 | 15.5 |

| PE750×1060 | 630 | 75-200 | 80-160 | 255 | 110 | 30.5 |

| PE900×1060 | 720 | 230-350 | 180-280 | 250 | 110 | 32.6 |

| PE900×1200 | 750 | 95-165 | 87-180 | 225 | 132 | 49 |

| PE1200×1500 | 1020 | 150-300 | 270-500 | 180 | 200 | 88 |

| PEX150×500 | 125 | 10-40 | 45059 | 300 | 11 | 2.2 |

| PEX150×750 | 125 | 10-40 | 45068 | 300 | 15 | 3.2 |

| PEX250×750 | 210 | 15-50 | 45160 | 300 | 22 | 5.6 |

| PEX250×1000 | 210 | 15-50 | 10-32 | 300 | 30 | 6.85 |

| PEX250×1200 | 210 | 15-50 | 12-38 | 300 | 37 | 7.52 |

| PEX300×1300 | 250 | 20-90 | 10-65 | 300 | 75 | 12.5 |

| PEX400×1200 | 340 | 20-80 | 18-60 | 275 | 55 | 11.7 |

PEY Series:

| Model | Way-in size (mm) | Maximum material granularity (mm) | Discharge port size (mm) | Capacity (m3/h) | Power (kw) | Weight (motor excluded)(t) |

| PEY-300×1300 | 300×1300 | 250 | 20-90 | 10-65 | 75 | 16.3 |

| PEY-400×600 | 400×600 | 340 | 40-90 | 10-40 | 45 | 11.8 |

| PEY-400×750 | 400×750 | 340 | 40-90 | 12-50 | 55 | 13.4 |

| PEY-500×750 | 500×750 | 425 | 50-100 | 34-55 | 75 | 15.5 |

| PEY-600×900 | 600×900 | 500 | 65-160 | 30-75 | 90 | 23 |

| PEY-700×1060 | 700×1060 | 630 | 170-300 | 60-200 | 90 | 35.4 |