Powder Mixer

-

High Intensity Mixer

The current application includes: powder mixing with greatly different components(such as iron powder and bentonite), powder and binder mixing, semisolid material mixing(such as sludge and powder) and high temperature material.

Send Email Details

Advantages: 1. Great mixing result can be achieved in a short period of time.

2. Keep producing high quality mixed material for a long term.

3. Easy maintenance of structural components, reliable operation,less vulnerable parts.

4. Continuous operation mode. -

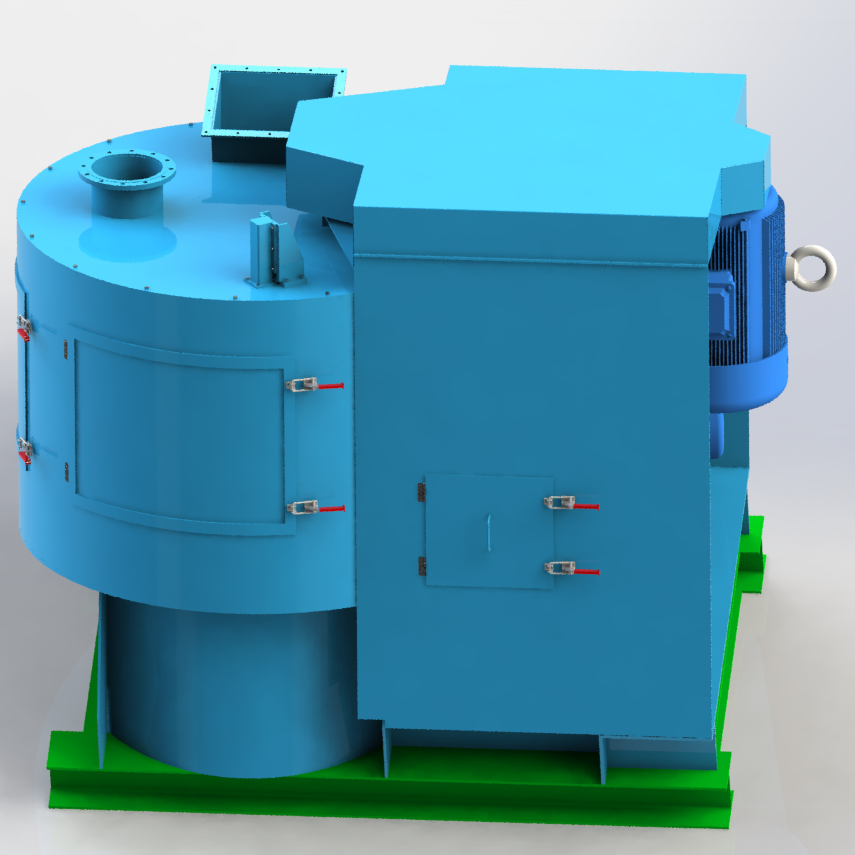

Vertical High Intensity Mixer

1. Product function

Send Email Details

- Mixing

- Mixing granulation

2. Structural parts

- less wear

- less maintenance -

Pin Mixer Granulator

Pin mixer is used for micro mixing and granulation with suitable materials. Mixing and granulation are done in the same unit. Powder and liquid materials are converted into small pellets by means of high-speed rotors and pin shafts.

Send Email Details

According to different process, the liquid can be water,binder, oil or surfactant. Whereas, the powder can be ceramsite sand, carbon black, cement kiln dust, pigments, coal dust, pesticides, arc furnace dust collection ash, limestone powder, graphite, coke, petroleum coke powder and silica fume, bauxite, etc.

According to user's requirements and operating conditions, this series of equipment has a variety of configurations. Model MP--is the continuous operation mixing granulator, and model MPJ- is the intermittent operation mixing granulator. Compared with the continuous mixing granulator, the product qualification rate of intermittent operation equipment is higher, reaching more than 70%, but the single-machine processing capacity is lower. -

High Speed Shear Mixer

KZJ high speed shear mixer is developed by our company. It is mainly applied to fine mixing operation for a variety of viscous powder materials with high water content. For example, phosphogypsum made of lightweight blocks and bauxite tail preparation of low-temperature ceramic mixing operations. It has conveying section, mixing and pinching section and extrusion section, these three sections are relatively independent but also interact with each other. The accuracy of micro mixing can be achieved through the strong mixing and pinching.

Send Email Details

It has the characteristics of reliable operation, closed and continuous operation, high mixing accuracy and high production. -

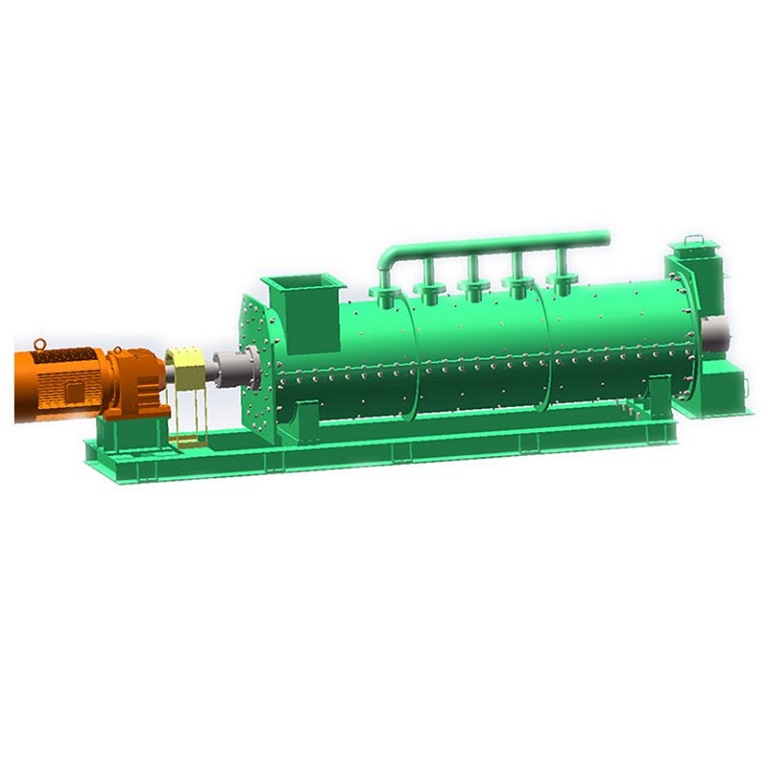

Twin-shaft Mixer

MTS twin-shaft continuous mixer adopts the screw blades to make the material move forward alternately within the machine, which has the characteristics of strong mixing ability and continuous and even feeding. It is suitable for mixing and humidifying loose materials, such as coal humidification, and it can also be used as a pretreatment equipment for fine mixing.

Send Email Details

Technical features:

Its continuity makes mixing in order.

The special designed shape of blades make it a efficient mixing. The blade arrangement angle along the axis is different, which is more conducive to the improvement of mixing accuracy.

The gentle mixing process does not break the material's initial status.

Blades are made with high abrasive resistance material, like hardfacing wear-resisting electrode, thermal spraying cermet and ceramic blade are available.

The transmission system uses twin-shaft reducer which is powered directly through universal joints, to achieve a pure torque input power.

When used for humidification, the special atomizing nozzle and liquid feeding system with adjustable flow rate can ensure uniform humidification of materials.