- : KAIZHENG

- : CHINA

- : To be confirmed

- : Sufficient

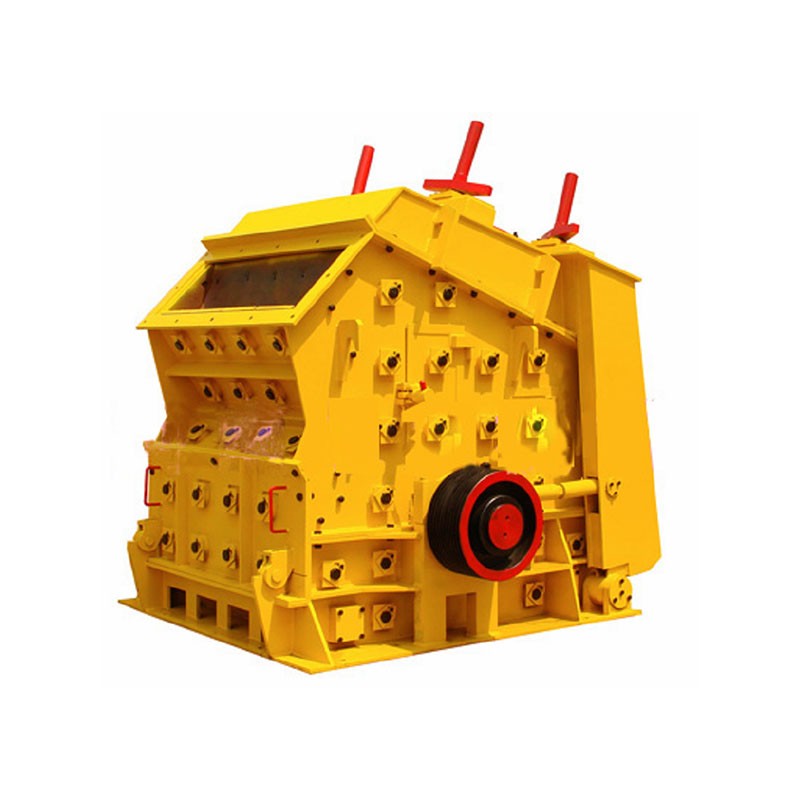

PFY-Hard rock impact crusher.

PCXK-Reversible hammer crusher.

PC-Hammer crusher. PCH- Ring hammer crusher.

PCF-High efficiency fine crusher (hammer crusher).

PFY- Hard rock impact crusher:

It is a series of machines designed for stone with compressive strength that greater than 300MPa and mohs hardness greater than grade 6. This machine consists the most famous design, analysis software and advanced computing technology. It is a kind of advanced new machine worlwide. The rotors of this machine have large moment of inertia, long service life, high output, and the finished materials are shaped into multi-ribbed body. All models are equipped with hydraulic opening, counterattack frame retreat device, larger size equipped with hammerhead lifting device.

Technical parameters:

| Number | Model | Input granularity (mm) | Output granularity (mm) | Capacity (t/h) | Power (kw) | Way-in Size (mm) | Weight (t) |

| 1 | PFY0808 | ≤200 | ≤30 | 30~50 | 55~90 | 500×830 | 7.1 |

| 2 | PFY1110 | ≤250 | ≤30 | 55~90 | 75~110 | 600×1030 | 10.3 |

| 3 | PFY1315 | ≤300 | ≤30 | 120~260 | 160~250 | 800×1530 | 23.5 |

| 4 | PFY1415 | ≤300 | ≤40 | 350~600 | 220~315 | 850×1530 | 28.6 |

| 5 | PFY1618 | ≤400 | ≤50 | 550~850 | 400~600 | 950×1830 | 37.4 |

| 6 | PFY1315C | ≤700 | ≤100 | 280~500 | 160~250 | 800×1530 | 23.1 |

| 7 | PFY1415C | ≤800 | ≤100 | 400~700 | 220~315 | 850×1530 | 30.9 |

| 8 | PFY1618C | ≤900 | ≤120 | 500~800 | 320~450 | 950×1830 | 38.6 |

PCXK-Reversible hammer crusher:

It is one of the main crushing equipment for fine limestone, coal or other brittle materials under medium hardness in metallurgy, building materials, chemical, water and electricity industries. It has the characteristics of large crushing ratio, high production capacity and uniform product size. Main performance advantages: (1) grate-free (2) The rotor can be reversed. After the hammer head runs in a certain direction for a period of time, the working side of the hammer head will be worn. At this time, the rotor can be rotated in reverse to make the other side of the hammer head work.

Technical parameters:

| Model | Rotor diameter / Rotor length (mm) | Input Granularity (mm) | Capacity (t/h) | Power (kw) | Output Granularity (mm) | Weight (t) |

| PCXK0606 | 600/600 | 60 | 10-20 | 45-55 | ≤10 | 3 |

| PCXK0808 | 800/800 | 70 | 20-40 | 75-90 | ≤10 | 5.5 |

| PCXK1010 | 1000/1000 | 80 | 60-80 | 110-132 | ≤10 | 7.5 |

| PCXK1012 | 1000/1200 | 80 | 70-100 | 132-160 | ≤10 | 9 |

| PCXK1016 | 1000/1600 | 80 | 90-120 | 185-200 | ≤10 | 11.5 |

| PCXK1212 | 1200/1200 | 80 | 100-130 | 220-250 | ≤10 | 13.5 |

| PCXK1216 | 1200/1600 | 80 | 130-180 | 280-355 | ≤10 | 17 |

| PCXK1413 | 1400/1300 | 80 | 200-250 | 400-450 | ≤10 | 22.3 |

| PCXK1616 | 1600/1600 | 80 | 280-300 | 450-500 | ≤10 | 32.3 |

| PCXK1618 | 1600/1800 | 80 | 350-400 | 630 | ≤10 | 39.8 |

| PCXK2022 | 2000/2200 | 120 | 450-550 | 630-800 | ≤10 | 89 |

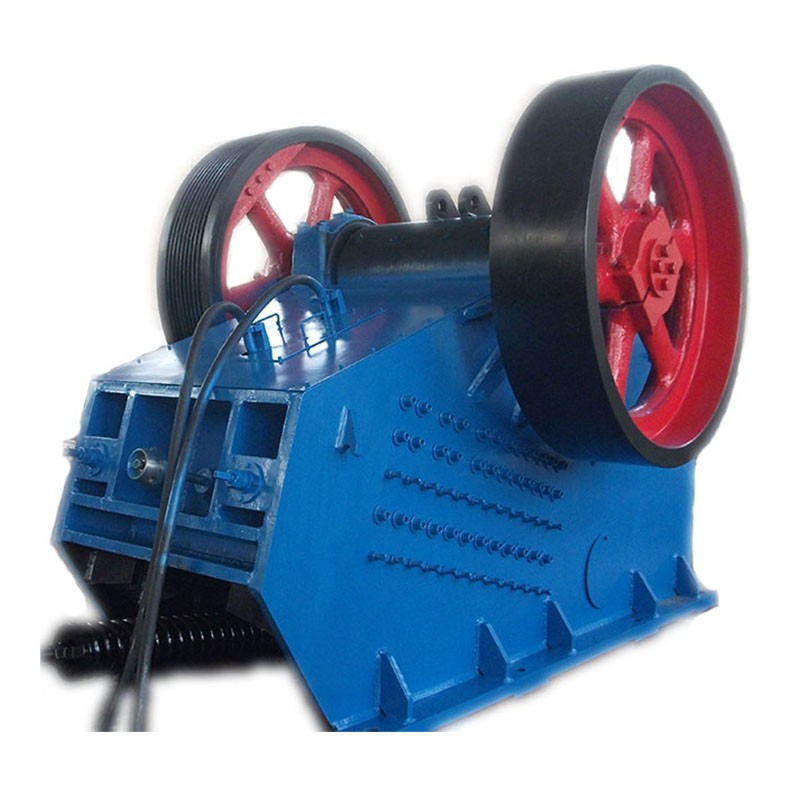

PC-Hammer crusher:

It is used to crush the material by colliding with the hammer body which rotates at high speed. The main component is the rotor with the hammer head. The motor drives the rotor to rotate at a high speed in the crushing chamber and hits the materials that entering the machine from the upper feeding port. The materials are crushed under the impact of the high speed hammer. A sieve plate is at the lower part of the rotor. The crushed material with qualified particle size is discharged through the sieve plate. The coarse particle that bigger than the sieve hole will continue to be hit by the hammer on the sieve plate, until it gets to a acceptable size. The adjustment of discharge size is achieved by changing the sieve plate with different specifications. The gap between the rotor and the sieve plate can be adjusted by changing mechanical structure.

Characteristics:

The working hammer head is cast with new technology with wear-resistant and impact resistant.

Granularity is adjustable according to specifications.

The sealed structure solves the problems of dust pollution and airframe leakage in the crushing workshop.

It has a beautifully designed shape, compact structure with less vulnerable parts and easy maintenance.

Technical parameters:

| Model | Rotor diameter (mm) | Rotor length (mm) | Max feeding size (mm) | Output granularity (mm) | Capacity (t/h) | Power (kw) | Weight (t) |

| PC(H)-0404 | 400 | 400 | 80 | ≤15 | 3—5 | 7.5 | 0.9 |

| PC(H)-0604 | 600 | 400 | 100 | ≤15 | 6—10 | 115—8.5 | 1.5 |

| PC(H)-0606 | 600 | 600 | 100 | ≤15 | 10—18 | 37—45 | 2.5 |

| PC(H)-0808 | 800 | 800 | 160 | ≤15 | 18—30 | 55—75 | 3.5 |

| PC(H)-1010 | 1000 | 1000 | 200 | ≤20 | 35—55 | 110—132 | 7.6 |

| PC(H)-1012 | 1000 | 1200 | 200 | ≤20 | 45—65 | 132—160 | 8.5 |

| PC(H)-1212 | 1250 | 1200 | 200 | ≤20 | 70—110 | 160—185 | 14.1 |

| PC(H)-1414 | 1430 | 1400 | 250 | ≤25 | 110—160 | 280 | 25.6 |

| PC(H)-1616 | 1600 | 1600 | 350 | ≤25 | 180—260 | 500 | 35.2 |

PCF-High efficiency fine crusher (hammer crusher):

It adopts advanced technology with high production and low energy consumption. Its performance plays a vital role in fine ore crushing equipments, and it is currently the most effective, practical and reliable crushing machine. The PCF high efficiency crusher is a perfect machine as it combines advantages of both hammer crusher and impact crusher.

Technical parameters:

| Model | Feed opening(mm) | Max input(mm) | Output granularity (mm) | Capacity(t/h) | Power(kw) |

| PCF800×400 | 400×185 | 40 | ≤5 | 20-30 | 22-37 |

| PCF800×600 | 500×250 | 40 | ≤5 | 35-40 | 37-45 |

| PCF800×800 | 550×330 | 40 | ≤5 | 35-45 | 37-45 |

| PCF1010×1010 | 1000×350 | 60 | ≤5 | 45-55 | 55-75 |

| PCF1200×1000 | 1200×400 | 80 | ≤5 | 80-110 | 75-90 |

| PCF1200×1200 | 1200×450 | 80 | ≤5 | 100-110 | 90-110 |

| PCF1400×1400 | 1500×500 | 80 | ≤5 | 100-150 | 160 |