- : KAIZHENG

- : CHINA

- : To be confirmed

- : Sufficient

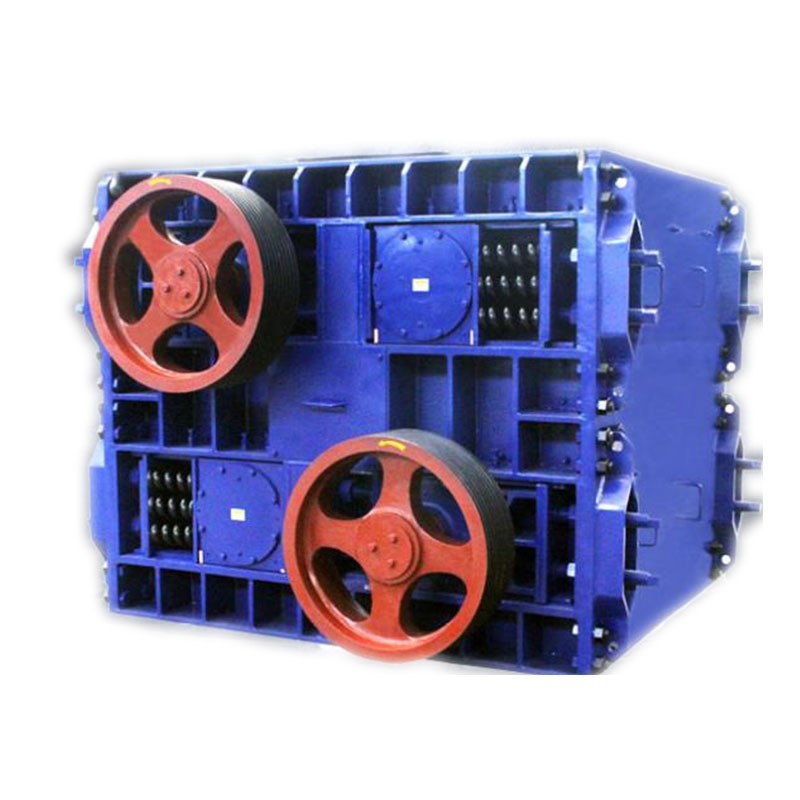

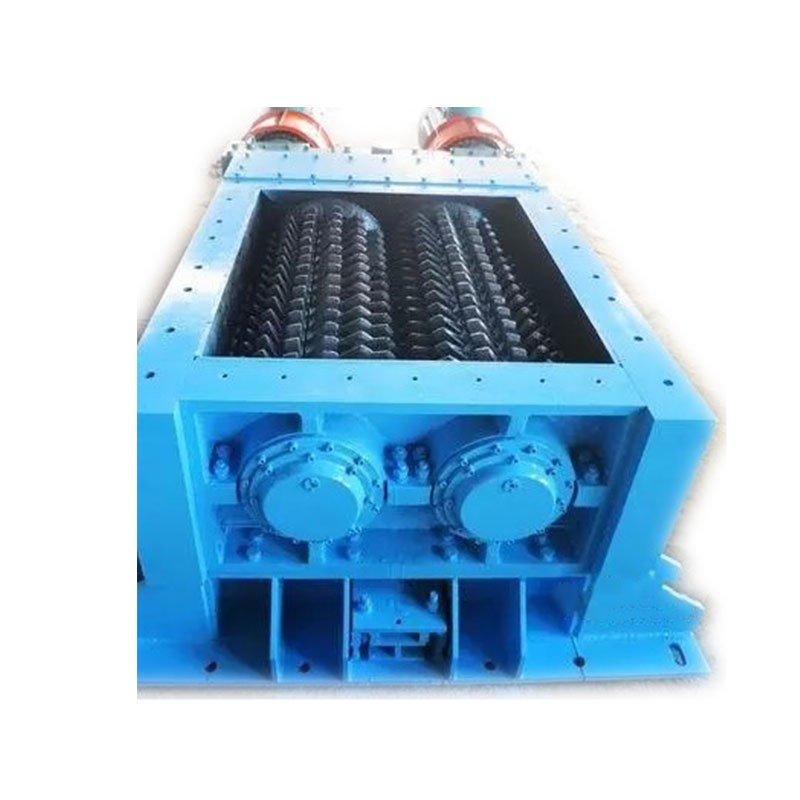

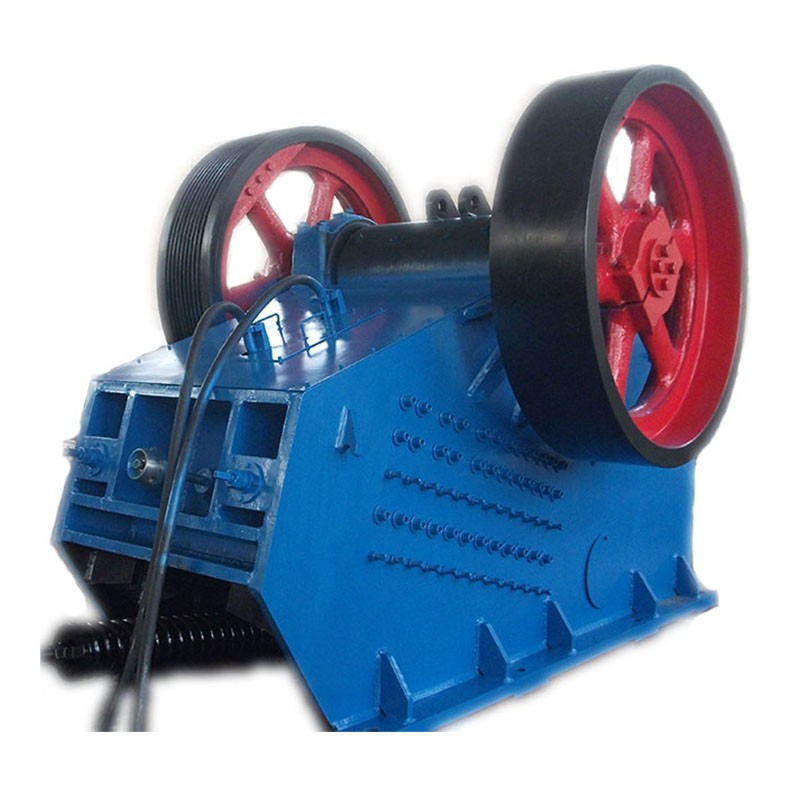

Double toothed roll crusher is divided into the spectral roll crusher (fine crushing), the toothed roll crusher (coarse and medium crushing). They are suitable for crushing the medium hardness materials, (such as coal, coal gangue, aluminum ore, laterite nickel ore, clay, etc.), which have a compressive strength of 140Mpa or below. Double toothed roll crusher is applicable to the metallurgical, chemical, mining, building materials and aluminum electrical industries.

Transmission system:

The transmission system is designed reasonably according to the specific model and working condition. There are three types of the system, which are single motor through the traditional bridge gear box, single motor through the double output shaft drive and double motor drive. No matter which type of transmission, the whole transmission chain is closed. Hydraulic couplers, safety couplings and optoelectronic parking devices can be selected as required.

Main structure:

According to different working conditions, the crushing roller center distance can be adjusted or fixed.

It can be a double rollers or four rollers. There is no limit for the water content of material. According to the material's viscosity, moisture, hardness and other working conditions to choose the tooth roller differential rotation to achieve mutual cleaning, the roller tooth can also be cleaned through the side comb plate.When the center distance of the tooth roller is absolutely adjustable, condidering the machine's size, the movable roller can choose mechanical spring energy storage or synchronous oil cylinder to ensure sufficient crushing force. Toothed roller structure is also diverse, there are integral toothed roller, combined toothed roller and so on.

Solutions for vulnerable components:

For the small size of the material (such as -5mm), use high quality spring steel with overall cold processing and heat treatment.

Material with general hardness uses surfacing welding carbide wear - resistant electrode.

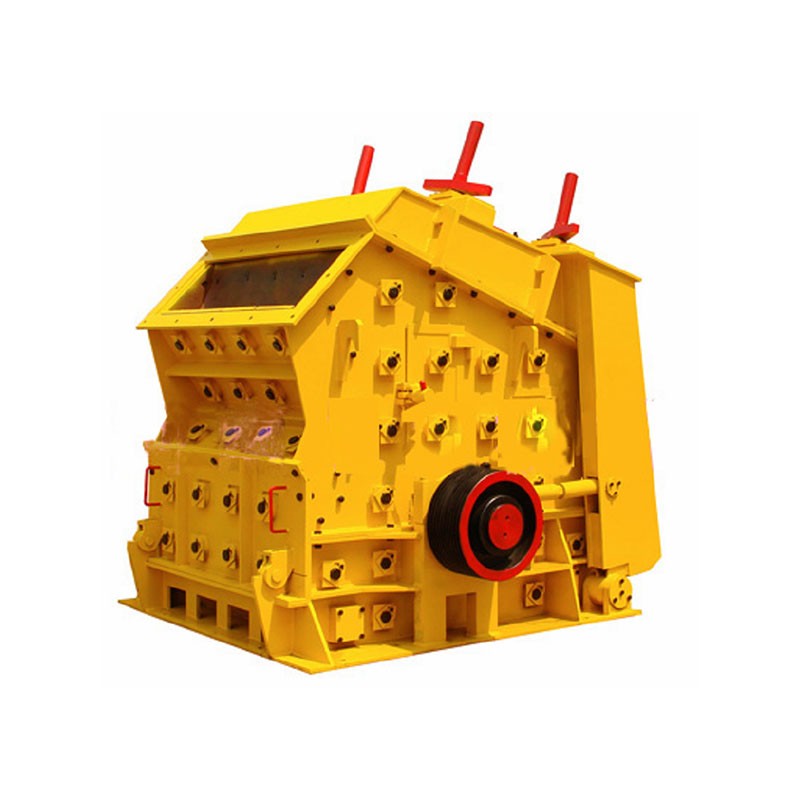

Crushers are divided into the following types:

2PG- Double roller crusher

4PG- Four roller crusher

2PCN- applicable materials: clay, laterite nickel ore, etc.

2PCM- applicable materials: coal, coke, quicklime, etc.

2PCQ- strength type, suitable for materials such as bauxite, coal gangue.

2PG/4PG Series:

Model | Roller diameter(mm) | Roller length (mm) | Input material granularity (mm) | Output material granularity (mm) | Capacity (t/h) | Power (Kw) | Weight (t) |

2PGM-0604 | 610 | 400 | 10-30 | 3-10 | 5-15 | 22 | 4.1 |

2PGM-0605 | 650 | 500 | 10-32 | 3-10 | 5.5-16.8 | 22-30 | 6.2 |

2PGM-0705 | 750 | 500 | 10-40 | 3-10 | 6-20 | 30 | 9.4 |

2PGM-0707 | 750 | 700 | 10-40 | 3-10 | 9-28 | 37 | 11.6 |

2PGM-0710 | 750 | 1000 | 10-40 | 3-10 | 11-40 | 45-55 | 13.5 |

2PGQ-0907 | 900 | 700 | 25-60 | 8-20 | 20-50 | 2x37 | 17 |

2PGQ-1210 | 1200 | 1000 | 25-80 | 8-20 | 45-90 | 2x45 | 26 |

4PGM-0705 | 750 | 500 | 30-40 | 3-5 | 15-22 | 22+18.5 | 17 |

4PGM-0907 | 900 | 700 | 30-40 | 3-5 | 25-30 | 37+30 | 17 |

4PGM-1210 | 1200 | 1000 | 40 | 3-5 | 40-50 | 55+75 | 58.6 |

Note:2PGM (Mechanical springs hold pressure) 2PGQ (hydraulic structure) | |||||||

Clay crusher:

Model | Roller diameter (mm) | Roller length (mm) | Input material granularity (mm) | Output material granularity (mm) | Capacity (t/h) | Power (Kw) | Weight (t) |

2PCN-0909 | 900 | 900 | 200 | -25-50 | 75-120 | 2×30 | 14.9 |

2PCN-1010 | 1000 | 1000 | 250 | -25-50 | 90-150 | 2×37 | 16.8 |

2PCN-1210 | 1200 | 1050 | 300 | -25-50 | 100-180 | 2×45 | 24.9 |

2PCN-1212 | 1200 | 1200 | 300 | -25-50 | 120-210 | 2×55 | 27.7 |

2PCN-1616 | 1600 | 1600 | 300 | -25-50 | 180-280 | 2×90 | 27.7 |

Note:

1. The clay crusher has an overall cleaning system.

2. The clay crusher has a higher revolving speed than the common double toothed roll crusher.

3. Its power is lower as the compressive strength of the material is generally lower.