A Study on the Influence of Drying and Preheating Parameters on the Roasting Properties of Limonite Pellets (2)

3. Test Results and Analysis

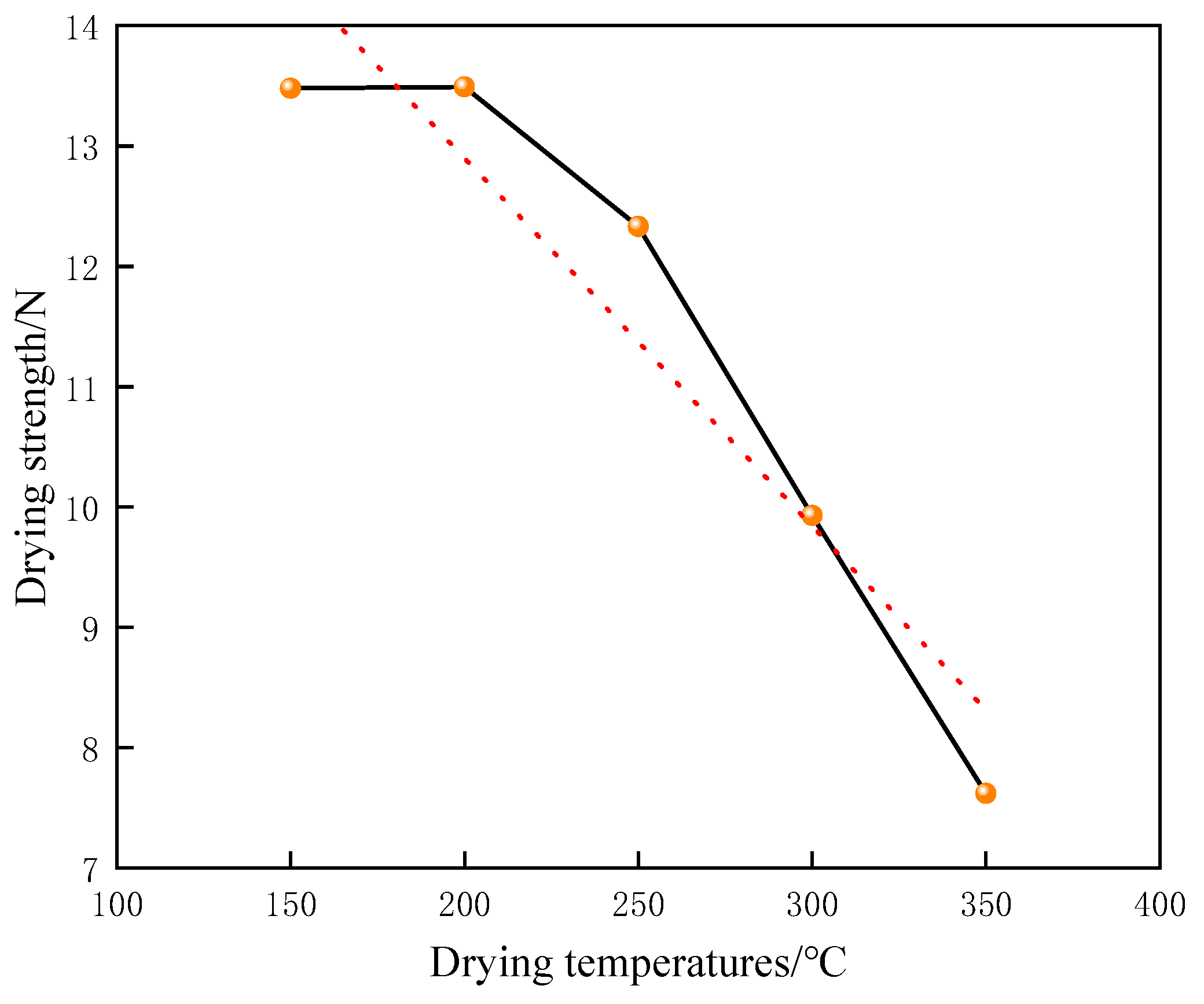

3.1. Effect of Drying Temperature on Pellet Strength

During the experiment, the proportion of bentonite binder was fixed at 1% for balling, and pellets of 8–13 mm particle size were selected for dry strength testing. As shown in Figure 5, the drying intensity increased and then decreased with the increase in drying temperature. Among them, the drying intensity at 200 °C showed the best performance, indicating that the drying temperature of 200 °C is the optimal temperature for the roasting process of limonite pellets. The 300 °C and 350 °C pellet performance strength was relatively poor because in the pellet muffle furnace heating process, due to the fixed period of time, the temperature rises too quickly, leading to the raw ball burst phenomenon.

Figure 5. Effect of drying temperature on drying strength.

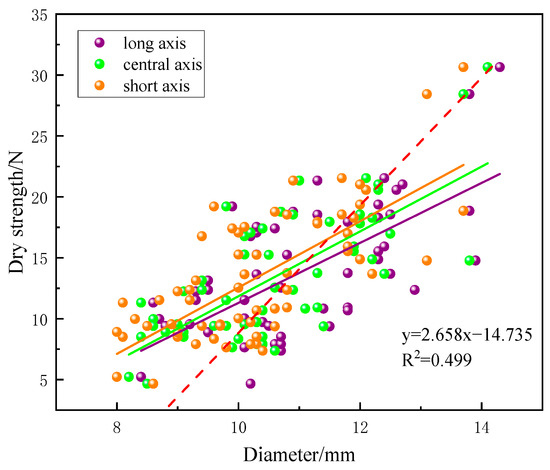

The experimental conditions were controlled unchanged, and the experimental data of 200 °C pellets were collated as shown in Figure 6: the drying strength increased with the increase in pellet diameter. The reason for this is that larger-diameter pellets have a higher drying strength due to their larger volume, better uniformity of volume contraction, and more uniform distribution of internal stresses. Smaller pellets, on the other hand, may shrink unevenly in volume due to uneven moisture loss during drying, and the pellets are more prone to rupture.

Figure 6. Effect of diameter on drying strength.

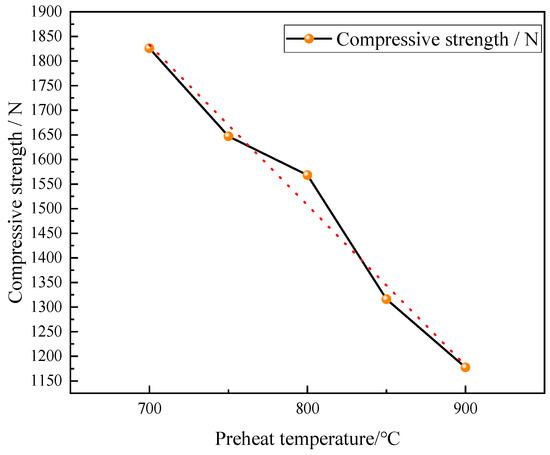

3.2. Effect of Preheating Temperature on the Compressive Strength of Pelletized Ores

In this experiment, the control of bentonite addition was 1% as the basis to study the effect of preheating temperature on the compressive strength of pellet ore, and compressive strength tests were performed on pellets with sizes of 8–13 mm. The experimental results are shown in Figure 7, and the highest compressive strength was 1825.95 N at a preheating temperature of 700 °C. This indicates that the preheating temperature of 700 °C just promotes the oxidation of limonite pellets, and the oxidation exotherm is the more active Fe2O3, which is favorable for the formation of crystal bonds between mineral powder particles. The experimental results at preheating temperatures between 700 °C and 900 °C showed that the compressive strength of the pellets showed a decreasing trend as the preheating temperature increased. Therefore, too low or too high a preheating temperature will lead to changes in the compressive strength of the pellet.

Figure 7. Effect of preheating temperature on compressive strength.

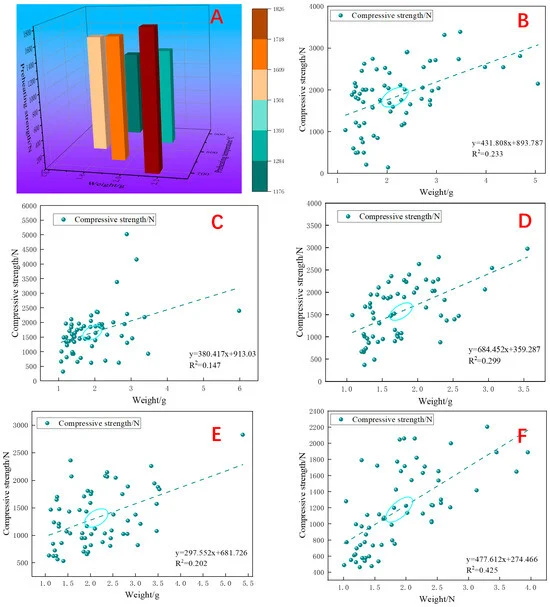

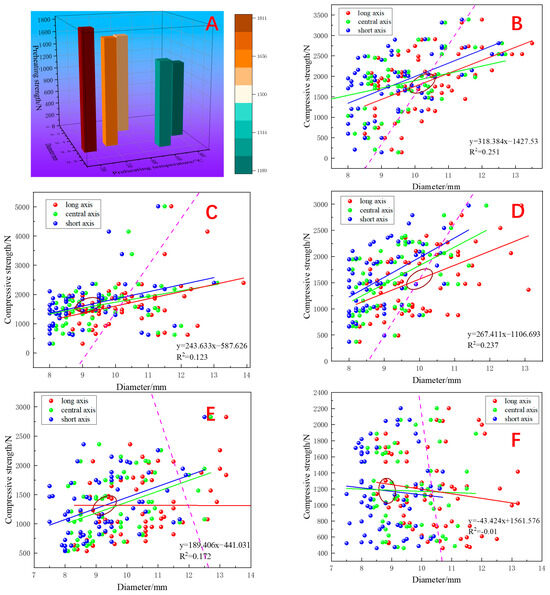

After exploring the effect of preheating temperature on compressive strength, Figure 8A represents a three-dimensional plot of the average weight of pellets against preheating strength at different preheating temperatures. As can be seen from Figure 8A, 700 °C corresponds to the best pellet strength. It can be concluded that the compressive strength of the pellet increases with an increase in the weight of the pellet under different preheating temperature conditions.

Figure 8. Effect of weight on compressive strength at different preheating temperatures. (A) Three-dimensional map of different preheating temperatures; (B) 700 °C; (C) 750 °C; (D) 800 °C; (E) 850 °C; (F) 900 °C.

Figure 9A represents a three-dimensional plot of the average diameter of the pellets against the preheating strength at different preheating temperatures. It can be seen from Figure 9A that 700 °C corresponds to the best pellet strength. A relationship between pellet diameter and compressive strength cannot be seen in Figure 9F, and the compressive strength is also relatively small. Compared with the compressive strength of pellets at the 700 °C preheating temperature, although the strength of some pellets at the 750 °C preheating temperature is high, it is not concentrated. It can therefore be concluded that the optimal preheating temperature of limonite pellets is 700 °C.

Figure 9. Effect of diameter on compressive strength at different preheating temperatures. (A) Three-dimensional map of different preheating temperatures; (B) 700 °C; (C) 750 °C; (D) 800 °C; (E) 850 °C; (F) 900 °C.

3.3. Effect of Roasting Temperature on the Strength of Pelletized Ores

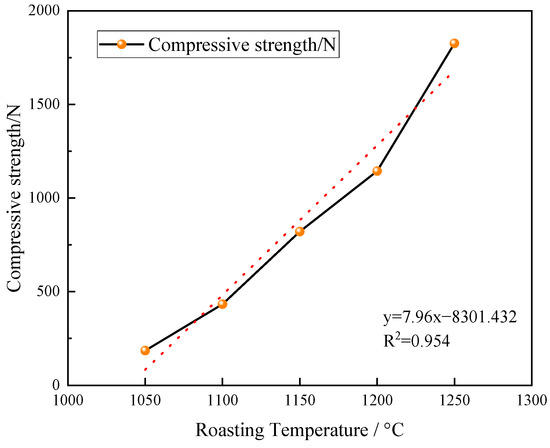

The proportion of bentonite was fixed at 1%, and the preheating temperature was 700 °C. Pellets with 8–13 mm grain sizes were screened to explore the effect of roasting temperature on the compressive strength of pellet ores. According to the experimental results, the effect of roasting temperature on the compressive strength of pellets is very significant, and the compressive strength gradually increases with the increase in roasting temperature.

Figure 10. Effect of roasting temperature on compressive strength of pellets.

3.4. Effect of Roasting Time on the Strength of Pelletized Ores

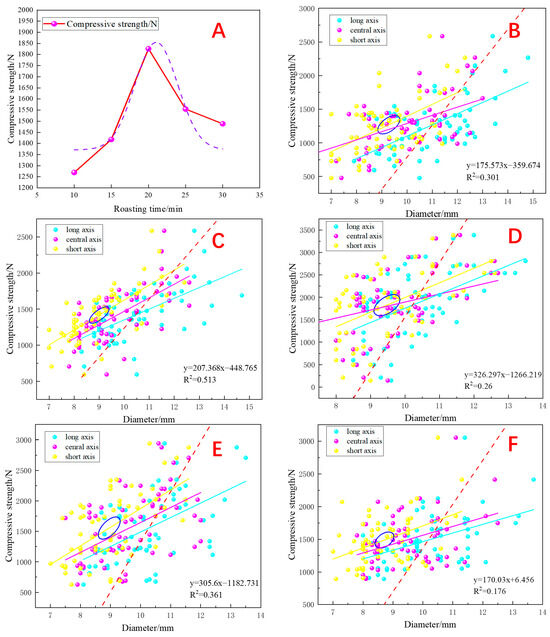

The experimental conditions were controlled unchanged to investigate the effect of roasting time on compressive strength. The experimental results are shown in Figure 11A, and the highest compressive strength was seen for the roasting time of 20 min. Recrystallisation and grain growth within a pellet takes time, and prolonged roasting allows these processes to be completed gradually, resulting in an increase in the compressive strength of the pellet. However, after a certain period of time, the compressive strength no longer improves. This is because the degree of crystallization within the pellet ore increases, leading to an increased expansion rate. As a result, the pellet may experience internal rupture or even melting, resulting in a reduction in its compressive strength.

Figure 11. Effect of diameter on compressive strength of pellets at different roasting times. (A) Roasting time; (B) 10 min; (C) 15 min; (D) 20 min; (E) 25 min; (F) 30 min.

From Figure 11, it can be concluded that the strength increases with increasing diameter, where it is optimal at a roasting time of 20 min. Analyzing the reasons, larger-diameter pellets have more particle connection points, resulting in closer internal mechanical connections and a more stable structure. It can also be seen in the figure that some of the small-grain-size pellets also perform better in terms of compressive strength. The reason may be that the small-grained pellet particles have a more uniform shape, which makes the particles have a strong bonding effect between them, and the close connection between the grains inside the pellet reduces the existence of pores and crevices, which enhances the overall structural stability and compressive strength. The conclusion shows that a pellet diameter of 8–13 mm is the most suitable size, and the pellet strength is also good and uniform.

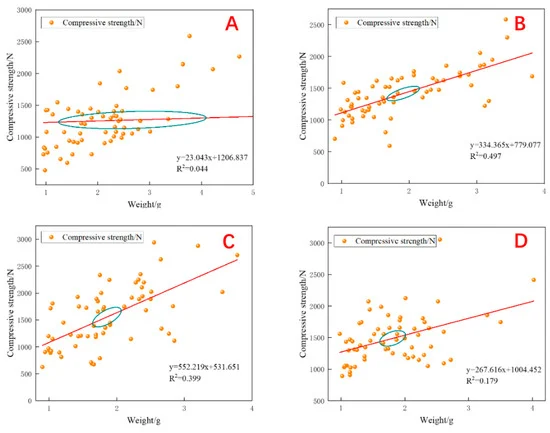

To further investigate the effect of roasting time on compressive strength, the effect of the weight of pellets on compressive strength was recorded separately for different roasting times in the experiment. At 10 min and 15 min of roasting, the compressive strength of the pellets increased with time. As the roasting time continued to be extended, the volume inside the pellet ore gradually increased due to crystallization changes. This resulted in a higher expansion rate within the pellet and the presence of surface cracks, ultimately leading to the low strength of limonite. As a result, the pellet strength was low and dispersed at 25 min and 30 min of roasting, as seen in the graph.

Figure 12. Effect of weight on compressive strength for different roasting times. (A) 10 min; (B) 15 min; (C) 25 min; (D) 30 min.

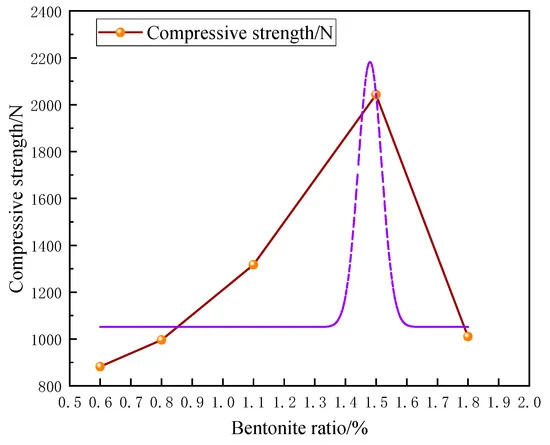

3.5. Effect of Bentonite Ratio on Compressive Strength

The effect of the bentonite ratio on the compressive strength of finished balls are shown in Figure 13. Bentonite can improve the particles between the iron ore materials, so that after roasting, the internal molecular bonding of the pellet becomes larger, and the strength of the pellet is improved. When the bentonite ratio continued to increase, a large amount of bentonite piled up in the material between the particles, leading to shrinkage, incomplete pore space, and large porosity after pellet roasting, and ultimately a decline in compressive strength.

Figure 13. Effect of bentonite ratio on compressive strength.

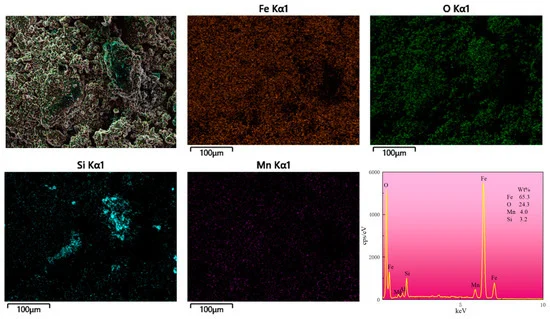

3.6. SEM-EDS Image Analysis of Limonite Pellets

Figure 14 shows the SEM-EDS images of the bentonite–limonite pellets. From the figure, it can be observed that after roasting under the condition of 1250 °C, the main components of limonite pellets were elemental iron and oxygen, which were uniformly distributed on the surface of the pellets. According to the results of the spectral analysis, the percentage of iron and oxygen was 89.6 per cent. With the addition of the bentonite binder, the pores of limonite pellets were uniformly distributed and interconnected, and such structural characteristics help to improve the physical stability and mechanical properties of the pellets. In addition, the iron (Fe) content of the bentonite–limonite pellets was 65.3 per cent. In contrast, the total iron content of limonite pellets was only 54.67 per cent, so bentonite increased the iron content of limonite pellets by 10.63 per cent.

Figure 14. SEM-EDS image of bentonite–limonite pellets at 1250 °C.

4. Conclusions

In this study, based on the multidimensional experimental results, limonite pellets showed the best results under the conditions of an optimal drying temperature of 200 °C, optimal preheating temperature of 700 °C, optimal roasting temperature of 1250 °C, and optimal roasting time of 20 min; the pellets with 8–13 mm grain diameter had the optimal size and uniform strength. In limonite pellets, when the amount of bentonite added reaches 1.5%, the compressive strength of the pellets reaches the highest value, meeting the needs of a general blast furnace. After oxidizing and roasting treatment, the crystal bridges between the grains of limonite pellets are more conveniently lapped, thus improving their compressive strength.

Chen, P., & Zhou, X. A Study on the Influence of Drying and Preheating Parameters on the Roasting Properties of Limonite Pellets. Minerals, 14(2), 166. https://doi.org/10.3390/min14020166

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).