- : KAIZHENG

- : CHINA

- : To be confirmed

- : Sufficient

Technical features:

The adjustable basket form has an uniform discharge with easy installation and maintenance.

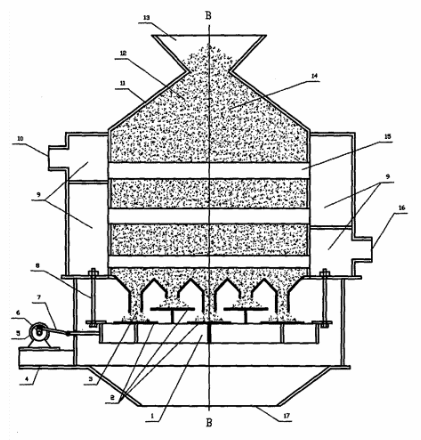

The whole furnace is designed as a trapezoidal shape, which is narrow at the top and wide at the bottom. So that the material will not stuck inside.

The position of hot air inlet is designed at the lower middle, the pre-drying distance is long with a good dehydration effect.

The upper part of the furnace is closed and the dust removal is done inside. Low wind speed carries out less dust, in the mean time, it is easier to observe the stock bin temperature, feeding and combustion condition.

It uses infrared camera for monitoring and automatic alarm device for temperature control.

The heat source of drying adopts boiler flue gas and automatic heating system with automatic coal feeding and slag removal. The design of double vertical air duct avoids the influence of kiln length and resistance on uniform air distribution.

Technical parameters:

-Dry condition: constant (wind speed, wind pressure, temperature).

-Drying method: positive pressure blast.

-Dust removal method: negative pressure wind.

-Process temperature: 150-200℃.(in general)

-Drying time:3.5-5.5h.

-Furnace temperature detection method: instrument display or point sampling.

-Source of hot air: exhaust gas, gas furnace, steam heating, coal burning and hot air furnace.

-Dry medium working mode: convection, radiation, conduction.

Electric control:

-The electric control system adopts centralized control, the unloading trolley can be controlled manually and automatically, the discharging system uses PLC centralized control, the discharging is uniform and the time can be adjusted.

-A multi-channel temperature control system is to detect the temperature of each part.

-Configure the monitoring system to monitor the dryer which is easy to operate.