Technology of Coal-based Direct Reduction Iron(2)——INMETCO method

1. Brief introduction to the development process of RHF technology

Basic introduction

RHF iron-making process is a non-blast furnace iron-making process. It has a history of nearly 40 years since the first RHF was built by Inco,Ltd in 1978. It originated in the United States, was promoted in Japan, and developed in China.

RHF direct iron smelting can be divided into INMETCO method, DRYIRON method, FASTMET method and ITKM3 process due to the different raw material processing conditions and product quality requirements.

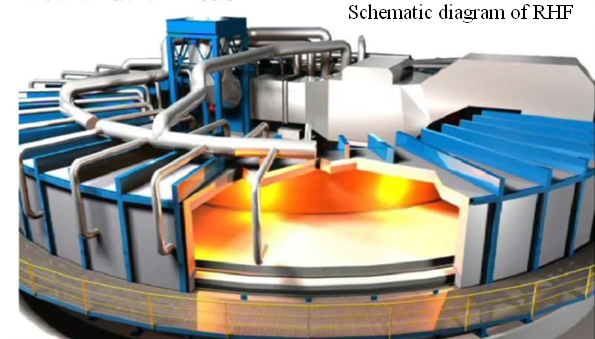

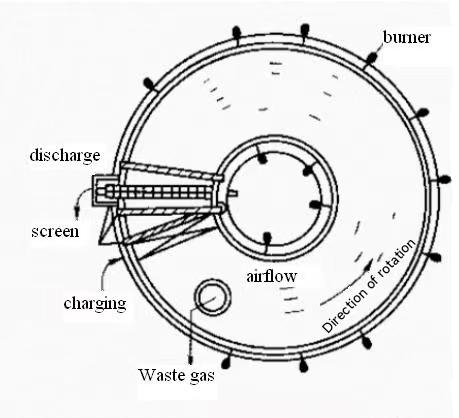

RHF furnace process is evolved from the circular heating furnace used for steel rolling. It has an annular furnace and a rotating furnace bottom, and the materials to be reduced are evenly spread on the furnace bottom which can rotate along the circumference. The furnace is a fixed and relatively sealed annular container, and there are many groups of gas burners arranged on the walls inside and outside the furnace. Temperature control and atmosphere control are realized by automatic control valve device and monitoring element according to different zones.

Only 1-2 layers of cold consolidated carbon pellet charge is loaded into RHF from the charging area, and the charge rotates with the bottom of the furnace without being squeezed. It was first heated to more than 1000℃ in the preheating zone, and then heated for 10-20min in the reduction zone of 1200℃-1400℃. In the reduction zone, Fe and K, Na, Pb, Zn and other oxides in the burden are self-reduced by the carbon in the pellet containing carbon. K, Na, Pb, Zn and other elements are removed in the form of gas with the flue gas. The reduced metallized pellets are discharged after cooling and cooled, and some of them are reoxidized, and the metallization rate is reduced. The flue gas generated by gas combustion and reaction flows in the opposite direction to the charge rotation, and finally flows into the exhaust gas purification treatment and waste heat recovery system.

There is a water seal between the furnace and the rotating bottom to prevent the escape of smoke and dust.

2. INMETCO method

2.1 Simple introduction

Developed by Inco In Canada, the plant was built in Elwood, USA in 1978 to deal with 80,000 tons of solid waste annually. It is used to recover nickel, chromium and iron from alloy steel smelting waste. Its process features are as follows: After mixing electric furnace ash, gas ash and reducing agent, carbon pellets with a diameter of 7-13mm are made by disk pelletizing machine. The pellets are quickly heated to 1300℃ for reduction in RHF, and the reduction process takes about 12 minutes. Meanwhile, heavy metal oxides are reduced and volatilized, and the rich zinc oxide ash containing more than 60% Zn and Pb is collected through cloth bag dust collection. The temperature of the discharge penalty ball is about 1250℃, and the energy required in the whole process comes from the preheating of flue gas in different sections or the combustion of gas. The precise control combustion system is designed to ensure that the combustion in different sections of the furnace is controlled according to the heat balance of the reduction process. Inmetco furnace has been successfully operated for more than 30 years, due to its DRI products containing 5-10% nickel chromium, With good economic benefits, it has become the solid waste treatment center of stainless steel factory designated by the United States government.

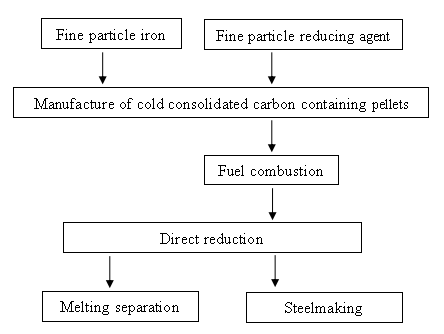

2.2 The basic process

2.3 Characteristics of INMETCO Method

The most prominent feature of this process is the use of carbon-containing pellets, with coal or coke powder as reducing agent, a layer of uniform thickness of about 3 times the diameter of the pellets on the bottom of the furnace.

With natural gas as fuel, high temperature gas is blown into the furnace to flow in the opposite direction from the bottom of the furnace, and the heat is transferred to the charge. Because of the thin material layer, the pellet heats up rapidly.

In the pellet containing carbon, ore powder and reducing agent have good contact conditions, at high temperature, reduction reaction speed at high speed, after 15-20min reduction, the pellet metallization rate can reach 88%-92%.