Sintering Mixed Granulation Process (1)

Mixed granulation process is a very important link in sintering production process. Intensive mixer is to mix all kinds of materials in the batching process evenly. Granulation is to make materials into mixed materials with appropriate particle size and good air permeability.

Purpose of mixed granulation:

1. Mix all kinds of materials prepared in the batching room evenly to obtain a mixture with relatively uniform components.

2. Adding moisture necessary for the sintering material in the mixing process so that the sintering material is wetted by water.

3. Granulation of sintered materials is carried out to obtain a mixture with suitable particle size and good air permeability.

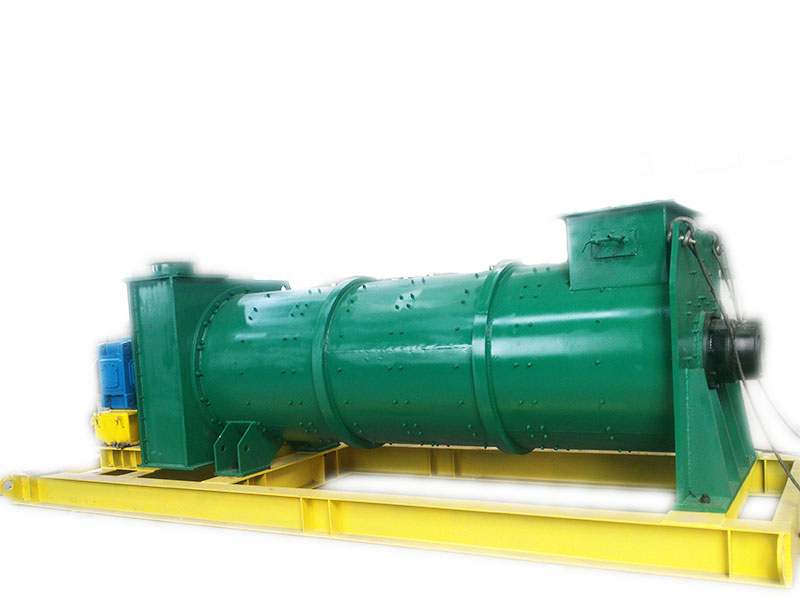

According to the number of mixing stages, there are one-stage, two-stage and three-stage processes for mixed granulation. The one-stage mixed granulation process uses a one-stage cylindrical machine to complete the mixing of sintered materials and the granulation of fine-grained materials. This process has been applied in early sintering production, and the raw material conditions are mainly coarse-grained fine ore. The two-stage mixer mainly completes the granulation of the mixture. However, with the development of large-scale sintering machines, the three-stage mixed granulation process is gradually adopted due to the need to adopt measures to strengthen treatment for thick layer sintering technology. With the development of related mixing technology, the particle size of sintering raw materials decreases and the variety of raw materials increases. Some sintering plants have already started to use intensive mixers to replace the cylindrical mixers in the first stage.

Mixing Granulation Process Using Intensive Mixer

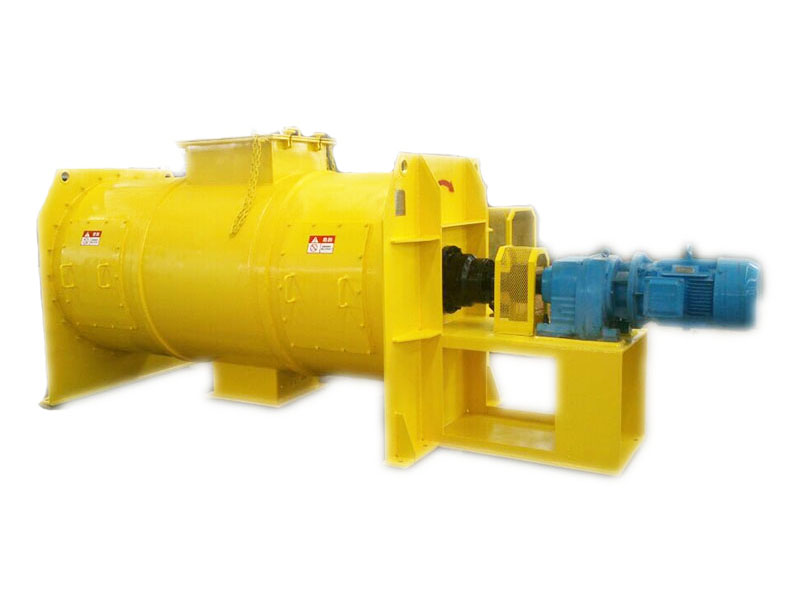

In sintering engineering, with the increase of concentrate ratio and the addition of various other iron-containing materials, higher requirements are put forward for the mixing of materials. Therefore, it is necessary to adopt appropriate mixed granulation technology and equipment. High intensity mixers are generally used to replace a section of cylindrical mixers. The mixing and granulation process using a high intensity mixer can also be divided into two-stage and three-stage types. The high intensity mixer is generally used as the mixing equipment for the first stage, while the cylindrical granulator is used as the granulation equipment for the second and third stages. An intensive mixing two-stage mixing granulation process is adopted.

The cylinder granulator in the two stages can be either a single large-size cylinder granulator or a plurality of small-size cylinder granulators arranged in parallel. Three-stage mixing and granulation process, i.e. One stage uses a high intensity mixer as the mixing equipment, and the two stages and three stages use granulators as the granulation equipment. Due to the structure of the powerful mixer, The interior is equipped with a rotor, A blade is arrange on that rotor, However, the sintering return ore has a great influence on the service life of the paddle. Therefore, considering the problem of overhaul of the high intensity mixer, the returned ore does not directly enter the mixer, but is added to the belt mixer after the strong mixing. The materials enter the granulation stage after the strong mixing, or bypass is set at the strong mixer. When the strong mixer is overhauled, the materials directly enter the subsequent mixer without passing through the high intensity mixer.