Manganese fine ore is treated by briquette method

Manganese powder ore generally refers to fine-grained concentrates obtained by beneficiation, and fine-grained materials containing manganese such as soot and ash obtained from smelting manganese ferroalloys in blast furnaces and electric furnaces. The briquette method one of the manganese powder ore agglomeration methods.

1. Advantages of briquette method

1.1 Flexible scale and moderate construction investment: 1.5-2 million investment can be used to build briquette production line, which can greatly reduce flying loss and improve operating conditions.

1.2 It is beneficial to improve product quality and reduce power consumption: briquette method, such as using organic matter such as pulp and syrup waste liquid as binder, completely eliminates harmful impurities, which can reduce power consumption and improve production efficiency due to the reduction of slagging amount.

1.3 Composite pellets (carbon-containing pellets) containing reducing agent can be prepared to improve production efficiency: the pellets prepared by fully mixing manganese concentrate and coal, in the blast furnace, due to the multiple reduction effect of coal on oxides As well as zero-distance contact between materials and reducing agents, the reaction is fast and the efficiency is high.

1.4 Materials with a wide range of particle sizes can be used: the pelletizing method used in blast furnace ironmaking requires that the particle size of iron concentrate is - 200 mesh, accounting for more than 80% of the total concentrate, while briquette has a wide range of particle size requirements, even Partial - 5 mm materials can be added, and more than two materials with large differences in specific gravity can be pressed into pellets with uniform components.

2. Main technological characteristics of briquette

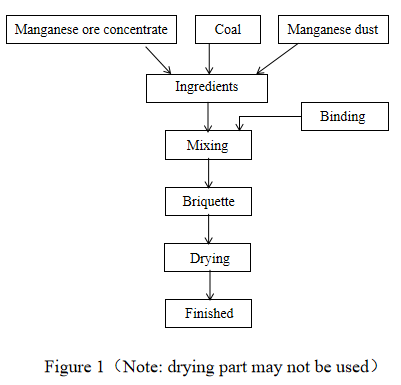

Briquette production technology is the use of binder, the material containing manganese and coal at room temperature using special ball pressing equipment forming, drying (200 ℃) directly into the furnace smelting. Basic technological process is shown in Figure 1

2.1 Size control range of materials containing manganese

The pelletization of the material with a certain particle size is better, when the concentrate below -5 mm accounts for 70%, the dust accounts for 30% when the pelletization is better, the compressive strength of more than 100 kg pellets can be pressed.

2.2 Binder

The function of the binder is to reduce the friction between the material particles and between the particles and the ball socket. The binder is generally a liquid or a soft and easily deformed substance, which has two functions:

①Evenly wrap a layer of binder on the surface of the material particles, which greatly reduces the roughness of the particle surface and is conducive to sliding between materials;

②When the material particles move relative to the mold, the binder lubricates the mold, so that the friction between the material and the mold is greatly reduced, which is conducive to forming balls and increasing the service life of the mold.

2.3 Feeding method

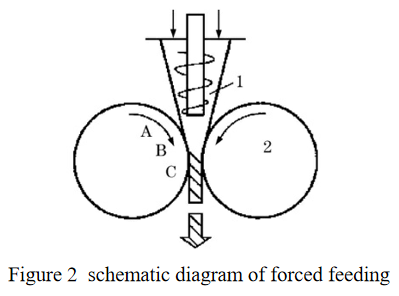

It is suitable to use strong feeding to suppress the pellet of manganese fine ore with many components and large proportion difference. Strong loading in addition to the feeding effects, also have A preloading effect on material, material damage "of the bridge effect", ruled out A part of the gas in the material, as shown, fill material at A ball and socket, due to the effect of spiral material in B and C can only be forced to stay inside the ball, as the roller turn out ball, is always full of before.

2.4 Role of coal in carbon pellet

Many applications show that the pellet containing carbon reflects good activity and reducibility in blast furnace ironmaking, and can effectively improve smelting coefficient and reduce coke consumption.

3. Conclusion

3.1 Due to the flexible scale and moderate investment, the briquetting method can be applied to the technological transformation of small and medium-sized soil sintering and disc sintering of ferromanganese alloys.

3.2 The use of briquette method is beneficial to improve product quality and reduce power consumption.

3.3 In carbon-containing pellets, due to the multiple reduction effects of coal on oxides and the zero-distance contact between the material and the reducing agent, the reaction is fast and the efficiency is high.