LT dust Cold Briquette

New Technology of LT Dust Caking

According to comprehensive analysis, LT dust can be reused while reducing environmental pollution by returning to converter for smelting after being lumped nearby, which is the best choice for its utilization mode. At present, there are two main lumping methods of LT dust: dry hot pressing and wet cold pressing, but both have obvious defects. If the advantages of the two can be combined, the problem can be solved. The new process mainly has the following main technical problems to be solved:

1. Pollution-free transportation of ultra-fine, high-temperature and spontaneous combustion dust.

2. High-activity CaO in dry dust reacts with water in binder or water in air, resulting in the strength reduction or even pulverization of finished balls.

3. Select reasonable raw material ratio, binder formula and ball pressing parameters for the treated LT dust to ensure that the product strength meets the requirements of transportation and large-scale use of converter.

Rapid Digestion Technology of LT Dust

Generally, the CaO content of converter LT dust is above 10%, and its activity is high. If it is not treated in advance, the CaO in the lump will be pulverized when it reacts with water during curing. Therefore, CaO in dust must be fully digested before briquetting.

The usual method for dust digestion is to soak in water, then dehydrate and then dry, but this will make the process complicated and costly. Therefore, how to ensure the rapid and full digestion of CaO in the powder under the condition of low water content is one of the key technologies before briquetting.

The cyclone steam digestion system specifically for LT dust will choose steam as the medium. Its working principle is to use saturated steam to eliminate the chemical reaction stress inside the dust removal dust, so that the steam and the dust are instantaneously mixed and contacted in a state of high-speed rotation, the moisture in the steam and CaO in the dust undergo digestion reaction, and at the same time, the steam condensed water will also destroy the surface structure of the dust particles, which is beneficial to the subsequent pelletizing process. Fine quicklime particles are evenly dispersed in iron-containing dust particles. In the cyclone digestion system, when dust and a certain amount of steam are rapidly stirred, due to the large internal specific surface area and pores of lime particles, water brought in from saturated steam will immediately penetrate into the pores, resulting in a strong hydration reaction, which will expand in volume while generating Ca (OH) 2. In addition, this is an exothermic reaction. The heat emitted can make the temperature of dust reach 80-90 ℃. With the increase of temperature, the reaction speed is accelerated, accelerating the digestion of CaO, while the remaining moisture in the steam after the reaction is discharged with the waste gas, thus realizing the low moisture digestion of dust.

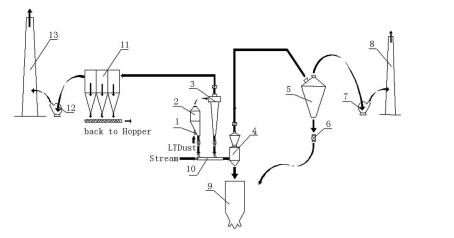

Cyclone digestion system consists of expansion bin, cyclone dust collector, digestion tank, throat, material steam separator and other equipment. Dust to be digested is transported into the expansion bin by wind, The mixture of material and gas is preliminarily separated in the expansion bin. Most of the dust enters the throat from the expansion bin through the ash unloading equipment after separation. A small amount of dust enters the cyclone dust collector along with the gas for further separation of material and gas. Waste gas is discharged into the dust removal system, and the remaining dust also enters the throat. Saturated steam telling rotation is introduced into the throat, the material and steam are fully and evenly mixed, and then enter the digestion tank, the dust is digested in the digestion tank and then enters the raw material warehouse, and the waste steam enters the material steam separator to separate the dust and steam.

1-LT dust inlet 2-expansion bin 3-cyclone dust collector 4-digestion tank 5-gas-solid separator 6-dust collector

7-induced draft fan 8-chimney 9-silo 10-throat 11-bag dust collector 12-induced draft fan 13-chimney