Key Equipment of High-pressure Roller Press

1. Steady current weighing bin

The roller press must be full of material operation, between the two rollers must ensure full of material, can not be interrupted. Therefore, it is necessary to set a weighing bin with a steady flow at the upper part of the inlet of the roller press. The capacity design of the weighing bin should not be too small, otherwise, the buffer room is too small, which will affect the normal operation of the roller press and cause great fluctuation of the quality of the cake after rolling. In addition, it is necessary to control the material level of the weighing bin. If the material level is too low, a stable material column cannot be formed above the roller press, which makes the weighing bin lose the function of forced feeding by material gravity, and it is easy to form the phenomenon of material bias flow and roll, causing the roller press to vibrate or stop.

2. Iron removal device

The wear-resistant layer on the roller surface of the roller press is easy to wear, especially sensitive to metal foreign bodies, so the materials fed into the roller press should remove iron thoroughly as much as possible. In addition to setting iron remover on the feed belt, it is necessary to set a metal detector on the feed belt. Moreover, in the production process, it should be ensured that the metal detector and the feeding system are linked smoothly and reacted quickly, so as to eliminate the mixed metal foreign matter in the material in time and avoid the metal foreign matter circulating continuously in the closed-circuit system composed of the roller press and the breaker and repeatedly damaging the roller surface layer.

3. Inclined insert board

The improper position of the inclined insert plate of the roller press will cause the pressure of the material column in the entrance of the roller press to be too large or too small, which will have an impact on the formation of a stable material bed. When the position is too high, the pressure of the material column is too large, there are many materials entering the roller press, and the roll gap is large, the materials will rush through the roller press or form a too thick material cake, which will increase the load of the next process, resulting in poor extrusion fruit and low finished product content. When the position is too low, the pressure of the material column is small, and the materials entering the roller press are small, it is difficult to form a stable and thick material bed, and the output is reduced. In severe cases, the equipment may vibrate and cannot run.

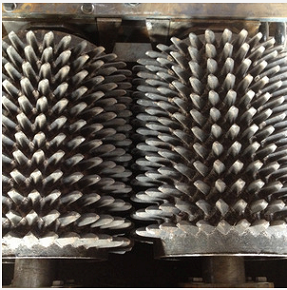

4. Break up the extension

A breaking machine is a new type of equipment for breaking and separating materials. After the extruded material enters the breaking machine, it is fully broken, and the breaking is based on the principle of centrifugal impact crushing. The material is accelerated after contacting the high-speed rotating discs, and the accelerated material is separated from the discs under the action of centrifugal force and shattered when impacting on the counter-attack plate. When the pulverized material enters the air separation area, the movement state of coarse powder changes little, while that of fine powder changes greatly, thus separating coarse powder from the fine powder. If the breakup fruit is reduced, the reasons such as wear of counter-attack liner, a slip of transmission belt of breaker, high moisture content of materials, and blockage of separation annular channel should be considered.

5. V-type separator

The V-type separator is a kind of static separating and dispersing equipment for roller press, which enters from left and exits from right, disperses the cake materials coming out of roller press, and then separates the qualified fine powder in the dispersed materials, which is beneficial to the smooth operation of roller press, improves the output of the system and has the function of drying. Simple structure and long service life of wear-resistant parts. The air volume is small, the pressure difference loss is small, and the fineness of the finished product can be controlled by adjusting the wind speed. Its function is basically the same as that of the breaking machine, and it is often used together with the roller press.