Enhancing Direct Reduced Iron (DRI) for Use in Electric Steelmaking(3)

DRI Melting

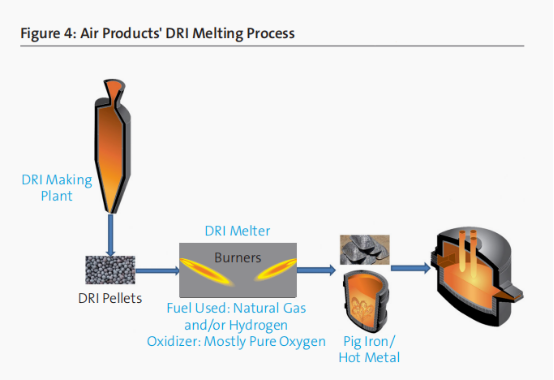

To further enhance DRI for steelmaking, it can be converted to pig iron or hot metal via melting. There are existing processes in the industry that use electric energy in furnaces such as submerged arc furnaces to convert DRI into hot metal. Air Products’ novel DRI melting process uses oxy-fuel combustion in place of electric power to accomplish this melting. Figure 4 provides a process diagram.

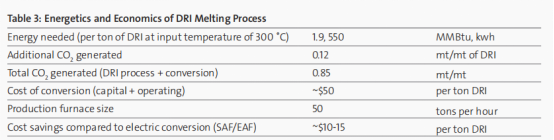

It is envisioned that the DRI produced by shaft furnace would, in a second step, be melted inside an oxy-fuel fired furnace to produce pig iron or hot metal that can be used in steelmaking. The furnace can be fired using natural gas and/hydrogen, with minimal additional CO2 emissions from the process. Table 3 shows the important parameters related to the Air Products’ DRI melting process.

Energy required per ton of DRI to melt is ~2 MMBtu, leading to additional 0.12 MT of CO2 per MT of DRI melted. The cost of conversion via the combustion route is estimated to be ~$50/ton of DRI, which by conservative calculations will be ~$10-15/ton DRI lower when compared to the electric melting route. The proposed process would be continuous, using a simple box-type furnace design equipped with oxy-fuel burners. DRI will enter from one end with slag and hot metal is extracted from the other end.

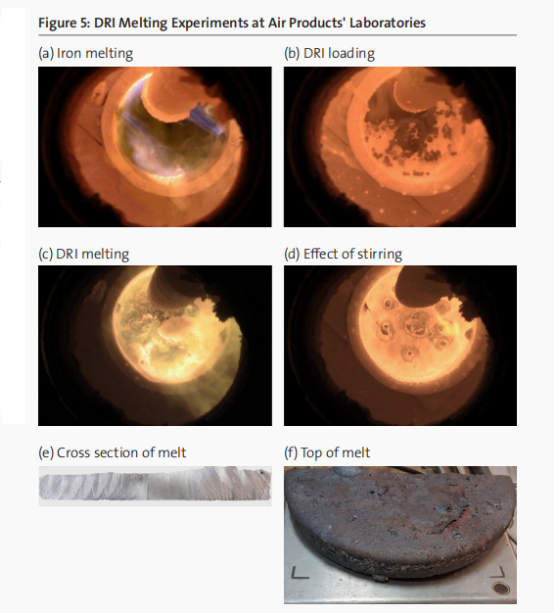

Results from initial investigation of this proposed process are shown in Figure 5. In laboratory experiments, DRI is melted using oxy-fuel burners in acrucible. A reducing atmosphere is created at the melt surface by modulating the burners. After melting, the liquid metal is cooled down under inert atmosphere and then analyzed for appearance and chemistry. As shown in Figure 5e and Figure 5f, after cooling, a clean iron cross section is obtained. In these initial melting experiments, minimal oxidation of iron is observed due to oxy-fuel burners. Gas stirring is employed to enhance mixing and heat transfer. The recovered slag weight (~2% of recovered product weight) matches well with the charge gangue weight, allowing for the conclusion that minimal additional slag is produced during melting.

Conclusions

The two novel approaches outlined in this paper present an opportunity to enhance DRI for use in electric steelmaking.

DRI preheating offers productivity and efficiency increase for EAFs with low additional CO2 footprint. Existing conveyor feed systems can be adapted to use the preheating furnace. Technical feasibility trials show no or minimal oxidation due to direct flame impingement. Next steps for this process development are to scale up the lab system, and field trial of the system at a mini mill.DRI melting takes the use of oxyfuel combustion one step further. This process offers an alternative to sourcing pig iron from blast furnaces.

DRI converted to pig iron offers a higher value source of virgin iron for steelmaking in EAFs leading to improved productivity and efficiency. This process, coupled with DRI production, can directly compete with the blast furnace route to produce pig iron, at less than half of the CO2 emissions. Technical feasibility trials show DRI can be melted using oxy-fuel combustion with good yield. Favorable economic and environmental parameters for the process warrant further investigation of the concept.