Development of 3D parametric CAD system for mixing equipment

Mixing equipment is widely used in food engineering, chemical engineering, biological engineering and other industries. They have an important impact on the process effect and product quality. Along with the gradually perfect and mature production technology, the technological parameters of mixing equipment, structure and stability, especially in the process operating conditions under the condition of same capacity only different, this kind of device is often just the difference of shape size, volume, power, size, number of assembly structure of the equipment, spare parts and types are basically the same. This provides necessary conditions for the standardization, standardization and modular design of mixing equipment. This paper briefly introduces the development of 3d parametric CAD system for mixing equipment.

1. Build knowledge database

1.1 Establishment and improvement of unit operation model

Qualitative analysis is made on the role of mixing equipment in the whole process, and the mathematical model of the equipment is established.

1.2 Establishment and improvement of equipment assembly structure

After the process purpose of the equipment is determined, the assembly structure of the equipment can be determined and improved. Common stirring and mixing equipment generally contains the following components: cylinder, head, transmission device, stirring device, shaft sealing device, pipe, accessories (hand hole, manhole, sight glass, etc.).

2. System Process Planning

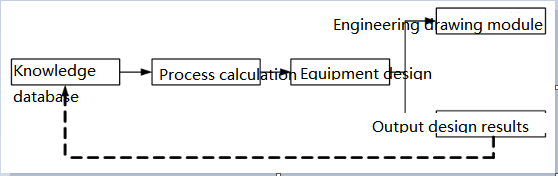

The specific design of mixing equipment includes three stages: process calculation, equipment design and engineering drawing. The diagram below:

3. Equipment design module

The design scheme after process calculation shall be the original condition of equipment design. Firstly, the overall structure is searched, confirmed and completed from the process model database, and then the specific parts and components are designed in combination with the equipment design database. The main design contents include: cylinder and head design, mixing device design, transmission device design, shaft seal device design, etc. The result of the design is saved in the design report, and the subsequent CAD drawing module reads relevant data from it, and draws or automatically generates the equipment engineering drawing.

4. Instance graphical database

In the specific design process, often has accumulated a large number of drawings, therefore, in addition to sorting out and improving the relevant process mathematical model and mechanical model, the system also needs to build the example graphics database. Instance graphics database and related functional modules are equivalent to a built-in PDM system. Existing drawings under the same working condition do not need to be re-generated or even redesigned, but can be retrieved and called directly through relevant interfaces. And new design of equipment can also be used by the database calls, such as motor, reducer, mixing blade, frame, coupling, seal, flange, such as standard graphics, implements the equipment, modularization and standardization of final drawings and can be used as a new instance is added to the database instance equipment, make full use of the design results, avoid the repeat design.

Example graphics database contains not only mature equipment drawings that can be called directly, but also parameterized standard graphics library, which is organically combined with related CAD system's own graphics library such as resource center. Parametric standard graphics library is based on 3D CAD system. This parameterized 3D library can be "created once and used forever", and 3d part models or assemblies created and generated on the basis of it can be used for preliminary finite element analysis or dynamic analysis in CAD system, and can also be exported to ANSYS for further analysis when necessary.

5. Conclusion

The CAD system of mixing equipment realizes process calculation, equipment design and drawing process standardization based on knowledge database, and the design efficiency is higher than the general design means, but also easy to ensure the design quality. The mechanism that the design results can be saved to the knowledge database improves the scalability of the system and reduces the workload of repeated design. The application of example graphics database realizes the parameterization, standardization and normalization of equipment design and drawing process, and creates engineering drawings more quickly and accurately.