Briquetting.Mixing.Grinding.Drying.HBI.RHF

Luoyang Kaizheng Environmental Protection Processing Equipment Co., Ltd is a collection of product research and development, manufacturing, independent trade high-tech enterprises. We have been focusing on developing integrated solutions for raw material preparation, ingredients, solid waste, residual materials and recycled materials to help customers more efficiently process various materials and convert them into value. Innovation of mixing machine, high pressure briquetting machine, grinding with roller press and other equipment in solving all kinds of industrial materials. Processing equipment with high viscosity in solvent recovery, evaporation, and other industries have unique applications. Compaction granulating device in all kinds of the comprehensive utilization of solid waste and other process is also significant.

-

30-01-2026

At present, China's petrochemical industry is confronted with the dual challenges of global overcapacity and high domestic raw material costs. Particularly, China lacks low-cost raw materials such as associated gas from oil fields and shale gas, which leads to persistently high production costs for core chemical products like ethylene. In 2023, there was a situation where related products in the United States were highly profitable while Chinese enterprises suffered comprehensive losses. How to break this deadlock? The article "Raw Material Substitution Facilitates High-Quality Development of China's Petrochemical Industry" published in the journal "Chemical Industry and Engineering Progress" has pointed out a clear path for us. This article, based on the core viewpoints of the original text, will help you understand the core logic and practical directions of raw material substitution.

-

18-11-2025

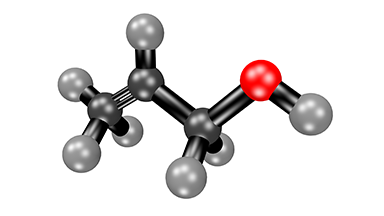

Introduction:With the deepening of the "Dual Carbon" strategy, cellulosic ethanol, as a core direction of second-generation bio-liquid fuels, has regained focus in the energy and chemical industry due to its significant potential in emissions reduction, avoiding competition with food supplies, and waste resource utilization. Through over a decade of technological accumulation and engineering demonstration, China has achieved a series of breakthroughs in core technologies, equipment, and industrial demonstration, moving from the "technology verification" stage to the critical "pre-commercialization" phase.

-

10-11-2025

As the "green hydrogen-to-ammonia (H2A) - green ammonia-to-hydrogen (A2H)" cycle model proposed in the paper "Research Progress and Prospects of Hydrogen-Ammonia Green Cycle" published in the journal "Chemical Industry Progress" continues to be implemented, China's hydrogen-ammonia green energy industry is experiencing explosive growth. Recently, a series of major developments have emerged one after another: Goldwind Science & Technology plans to invest approximately 18.92 billion yuan in a wind power-to-hydrogen, ammonia and methanol project, the first phase of Envision's Chifeng 1.52 million-ton green ammonia project has been put into production, and Jidian Co., Ltd.'s Da'an green ammonia project has set four global records. These milestones mark that this emerging track, which can solve the problem of hydrogen storage and transportation and promote the decarbonization of traditional industries, has moved from the laboratory to large-scale commercial operation.

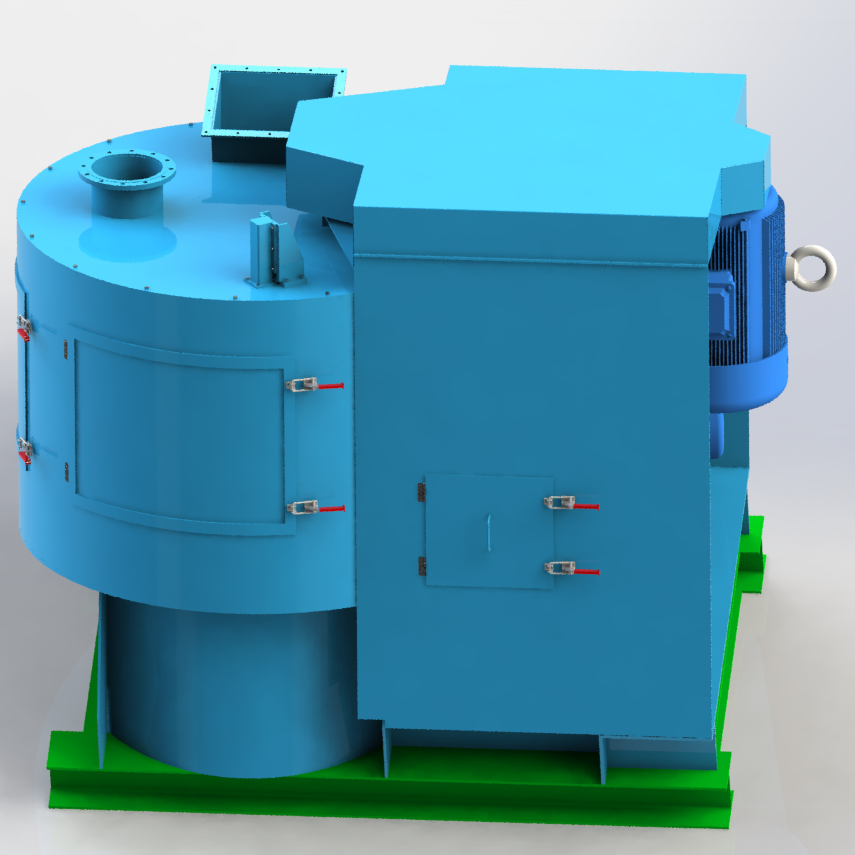

Vertical High Intensity Mixer

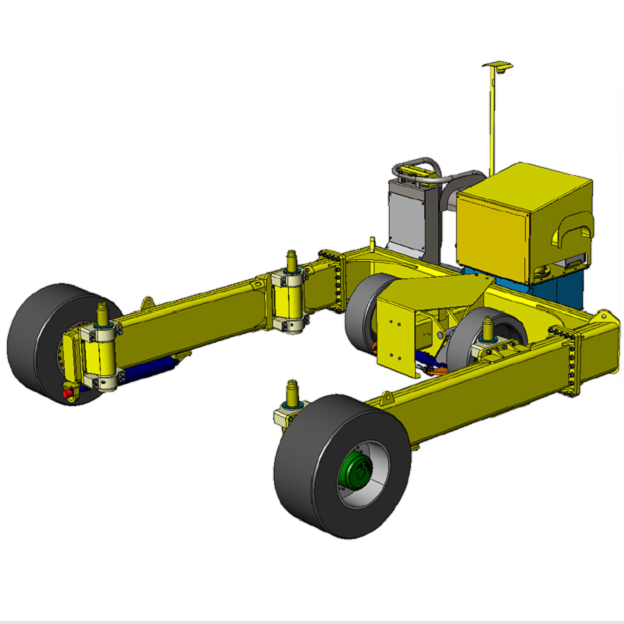

Feed Chute Transporter

Sludge Silo

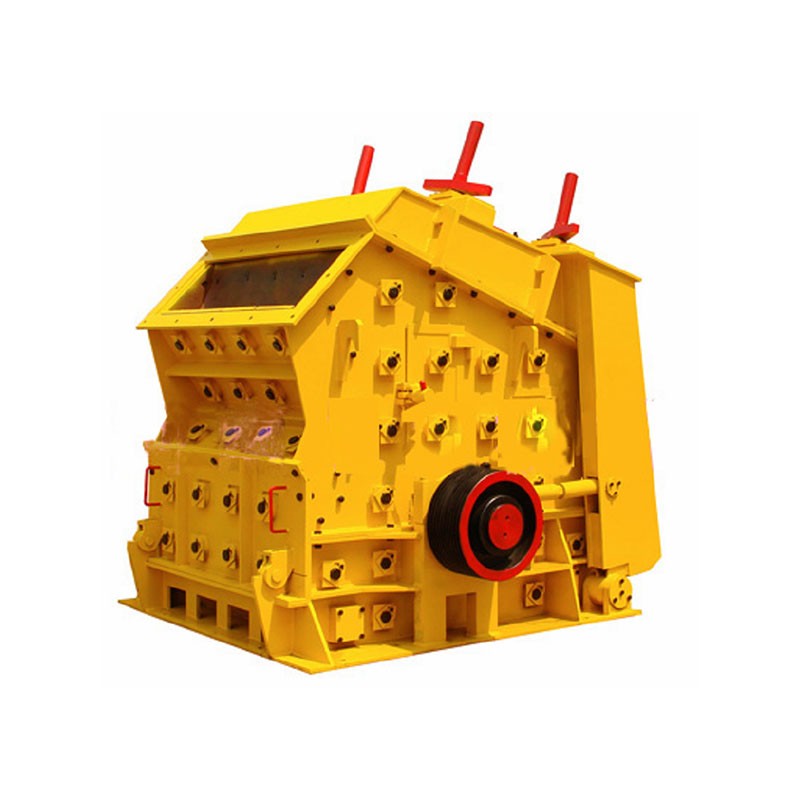

Impact Crusher

Double Toothed Crusher

Jaw Crusher

Vertical Dryer

Net Belt Dryer

Twin-shaft Kneaderreactor

Shear Mixer

Pin Mixer

Horizontal Mixer

Twin-shaft Mixer

Lab Scale Briquetting

Sponge Iron Briquetting

Sponge Iron

Grinding Roller Press

Granulating Machine

Briquetting Machine

High Pressure Briquetting